Where to Find an Activated sludge Solids Mass Balance Spreadsheet

For an activated sludge solids mass balance spreadsheet, click here for our download page. Obtain a convenient, easy to use spreadsheet for solids mass balance calculations for only $22.95. Read on for information about the use of an Excel spreadsheet for estimating the effect of recycle flow, BOD and TSS through solids mass balance calculations.

Background for an Activated Sludge Solids Mass Balance Spreadsheet

Several streams from sludge treatment processes are typically recycled back into the wastewater treatment plant inflow. Examples are sludge thickener overflow, anaerobic digester supernatant, aerobic digester supernatant, centrate from centrifuge dewatering, and filtrate from filtration dewatering. The liquid flow, BOD load, and TSS load in these recycled streams contribute to the wastewater flow to be handled by the mainstream wastewater treatment processes.

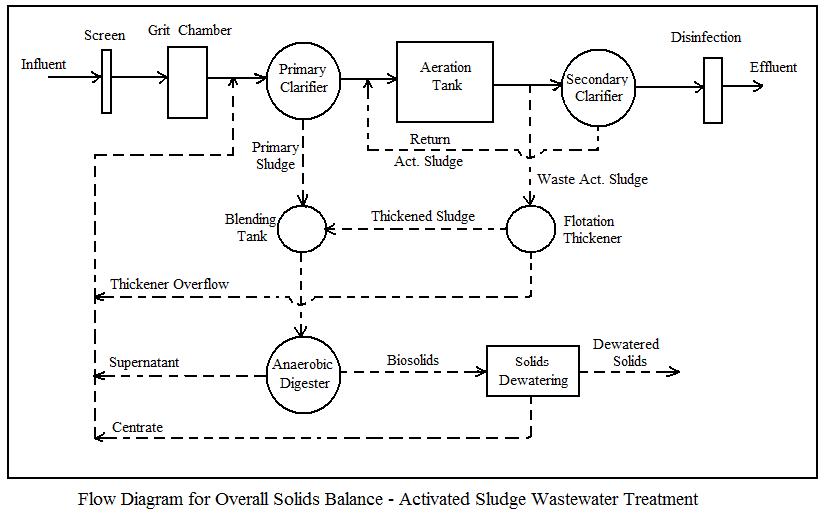

An iterative solids mass balance is an organized procedure for estimating the total flow rate, BOD load, and TSS load in the recycled flows from sludge treatment and handling processes. This type of calculation is illustrated in an eight page example in Metcalf and Eddy (Reference #1). The flow diagram below shows a typical set of sludge treatment processes and recycle flows for an activated sludge plant.

Influent and Effluent Input Information for the Spreadsheet

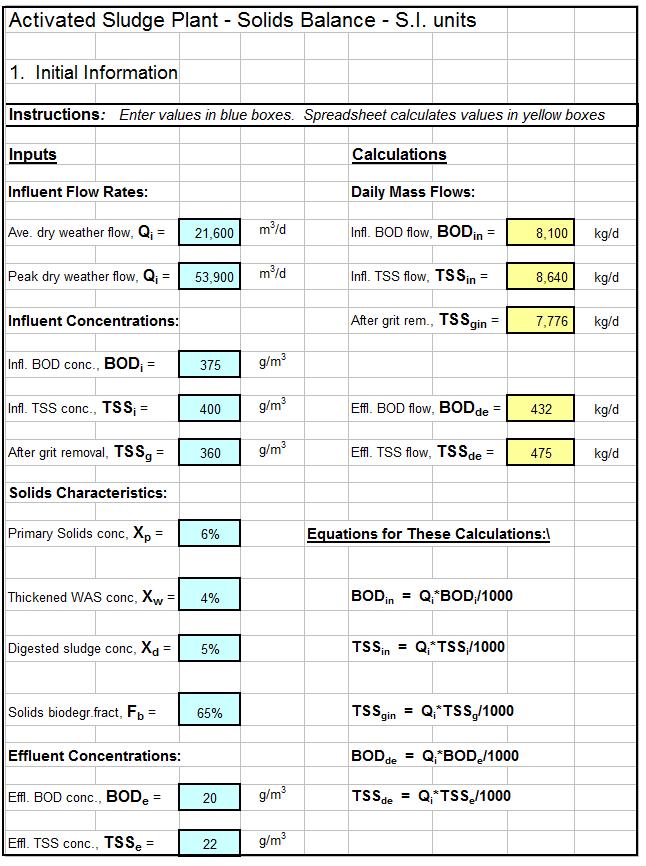

General information about the wastewater influent flow and characteristics will need to be input to the spreadsheet along with information about target effluent characteristics. The screenshot below shows typical influent and effluent inputs needed.

Solids Mass Balance Calculations for Each Treatment Process

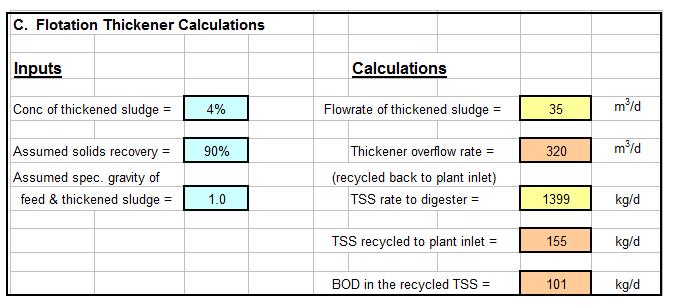

The next step is solids mass balance calculations for each of the treatment processes, leading to estimates of the recycle flow rate, BOD load and TSS load for each recycle stream. For a wastewater treatment plant with the flow diagram shown above, there would need to be solids mass balance calculations for the primary clarifier, the aeration tank/secondary clarifier, the sludge thickener, the anaerobic digester, and the sludge dewatering process. The screenshot below shows typical inputs and outputs for a solids mass balance over a sludge thickener.

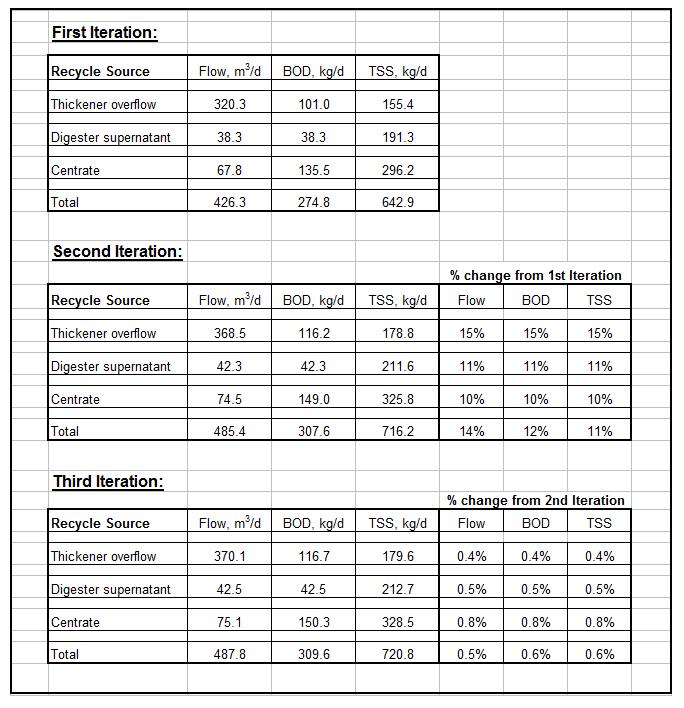

Similar calculations would be made for each of the wastewater treatment and sludge treatment/management processes, leading to information about recycle flow rate, BOD load, and TSS load, for each recycle stream as shown in the summary tables in the next section. After completion of the first iteration, the recycle flowrate, BOD load and TSS load are added to values for those parameters for the incoming wastewater and all of the solids mass balance calculations are repeated in a second iteration.

Summary Tables

The screenshot below shows a set of tables summarizing the results of the calculated recycles flows from the first three iterations. Spreadsheets are available to make this type of solids mass balance calculations in either U.S. or S.I. units at a very low cost (only $22.95) at our downloads page. These spreadsheets are set up to make the solids mass balance calculations for four iterations.

References

1. Metcalf & Eddy, Inc, (revised by Tchobanoglous, G, Burton, F.L., Stensel, H.D., Wastewater Engineering Treatment and Reuse, 4th Edition, New York, NY, 2003.

2. Bengtson, Harlan H., "Activated Sludge Calculations in a Solids Mass Balance Spreadsheet," an online blog article